发布日期:2022-10-09 点击率:123

Without a doubt, every engineer can point to a handful of what might be termed “superstar” sensors, improving quickly and dramatically with every iteration, targeting such high-profile applications as advanced driver assistance systems in the automotive sector and written about ad nauseam in the trades. There are also, and perhaps more importantly, several types of workhorse sensors that we rely on every day across myriad common but not glitzy applications. These sensors deliver what is needed, and do so consistently and reliably. The sensors tend to be devices that are easily slipped into applications, meeting required performance specs and at a price tag that can be tolerated.

For example, it is a dusty world and sensors that detect dust have been around for a long time. More governmental regulations exist today, however, as do definitions of what particulate level is permissible. Commodity dust sensors deliver important data, and they are now small enough to be incorporated into mobile devices. The simple detection of airborne dust is important for air purifiers, air conditioners and monitors used in many environments.

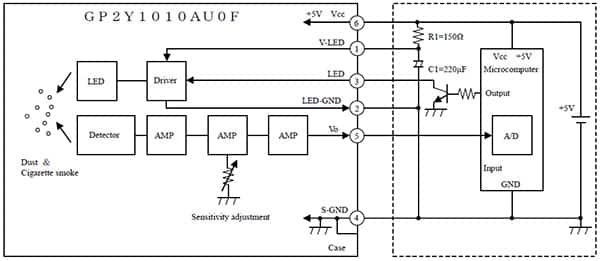

The GP2Y1010AU0F compact optical dust sensor from Sharp Microelectronics (Figure 1) provides air-quality information via an infrared-emitting diode and a phototransistor that are diagonally arranged in the device, detecting the reflected light of dust. based on an optical sensing system, the device is more compact, in a thinner package (46.0 × 30.0 × 17.6 mm) than its predecessors, and draws less power. It is especially effective detecting very fine particles such as found in cigarette smoke.

Figure 1: An example of system connection for the Sharp GP2Y1010AU0F optical dust sensor.

As with dust sensors, Honeywell’s LLE Series (Figure 2) targets a common application — in this case liquid level sensing — and adds some technological know-how. The LLE sensors incorporate a phototransistor trigger that prompts a digital output, which denotes the presence or absence of liquid.

In this sensor, an LED and phototransistor are located within a plastic dome at the head of the device. If no liquid is present, light from the LED is internally reflected from the dome to the phototransistor. When liquid covers the dome, the effective refractive index at the dome-liquid boundary changes and light from the LED escapes. Less light is received by the phototransistor and the output switches, indicating liquid is present.

Figure 2: The Honeywell LLE series derives its mode of operation from the principle of total internal reflection. Liquid-level sensing is very fast and almost instantaneous for water.

The sensor series provides an accurate, repeatable switching point; is microprocessor compatible; easy to install for less assembly time; and can be mounted in limited space. It is used in such applications as home appliances, spa baths and vending machines, as well as in the food and beverage industry, medical apps, and compressors and machine tools.

The industrial world is filled with differential pressure gauges. Differential pressure is defined as the difference between two applied pressures, and a differential pressure gauge is a visual indicator that measures and displays the pressure difference between two pressure points. It handles the mathematical operation of subtraction mechanically, eliminating the need for an operator or control system to watch two separate gauges and figure out the difference between the two from observation.

The D6F-PH digital differential pressure-type mass-flow sensor from Omron (Figure 3) is equipped with an I2C output and uses a proprietary Omron mass-flow MEMS chip. Omron redesigned the internal flow path to produce a low-flow, high-velocity/ -impedance sensor that will output differential pressure. This sensor will be available in three models, each for a specific pressure range and calibrated for numerous different gases.

Figure 3: The Omron D6F-PH differential pressure sensor is available in three models that are calibrated for a variety of gases.

Features include a high accuracy of ±3 percent R.D and the sensor is linearized and temperature compensated, uses digital output (I?2C communication), has high flow impedance to reduce the influence of a bypass configuration and is RoHS compliant.

Another common sensor is the force sensor or transducer that converts a mechanical force input into an electrical output signal. They work when the resistance of silicon embedded piezoresistors increases when they flex under an applied force, and the amount of resistance changes in proportion to the amount of force applied. This change in resistance results in a corresponding voltage output level.

An example is the FC22 Compression Load Cell by Measurement Specialties. It is a medium-compression force sensor that, because of its low cost and high performance, is rapidly expanding in use. The FC22 (Figure 4) offers normalized zero and span for interchangeability and thermal compensation for changes in zero and span with respect to temperature.

Figure 4: Measurement Specialties’ FC22 medium-compression force sensor creates new markets previously unrealizable due to cost and performance constraints.

The FC22 incorporates Measurement Specialties’ Microfused technology, which uses micromachined silicon piezoresistive strain gages fused with high-temperature glass to a high-performance stainless-steel substrate. The FC22 sensor measures direct force and is not given to the lead-die fatigue failure common with competitive designs which use a pressure capsule embedded within a silicone gel-filled cavity. Operating at very low strain levels, the technology provides an essentially unlimited cycle life expectancy, superior resolution, and high over-range capabilities.

Measurement Specialties points out that the FC22 cost optimization applies whether thousands or millions of load cells are used annually. The FC22 features small size, low noise, a high over-range capability, high reliability, low deflection, unlimited cycle life expectancy, and a fast response time.

The standard model is said to be ideal for a wide range of applications, and custom designs are also available. Applications include medical infusion pumps, robotics end-effectors, variable force control, load and compression sensing, exercise machines, contact sensing, weighing, and household appliances.

While sensors evolve according to the needs of the underlying applications they serve, there are a variety of devices that perform tasks extremely well, are low in cost, feature low power, and are easy to use and integrate. In this article we have presented a few unsung workhorse sensors that do all of this and more. In today’s fast world of sensor fusion, self-monitoring sensors, combination sensors and more, the workhorse sensor represents the majority of sensors specified by engineers for common everyday applications.

For more information about the sensors discussed in this article, use the links provided to access product information pages on the Digi-Key website.

下一篇: 断路器、隔离开关、接

上一篇: 索尔维全系列Solef?PV